Smoothen Flow, Remove Bottlenecks, Improve Safety and Minimize Costs

Space is expensive and quality is important.

The aim of improving a layout is to minimize expansion expenses by creating space and flow within the given constraints. The optimal layout process involves allocating space and arranging equipment and other physical assets in such a way that the operating costs are minimized and process efficiencies are maximized.

At the micro level (within a department), layout changes should be made when the need arises.

At the macro level (company-wide), management should analyze the layout at least once a year to ensure the changes at the micro level are positively impacting the overall flow, and make necessary adjustments as needed.

Layout optimization, on most occasions, doesn’t require significant investment. Typically, for a sub-optimal layout, 50-80% improvement can be easily realized.

Production efficiency levels depend on the optimal location of various machines, production facilities and employees’ amenities. An optimally laid out plant can ensure smooth and rapid movement of material, from the raw material stage to the finished product stage. Optimal layout facilitates the production of the correct quantity and quality of output at the lowest possible cost. Pull system, the preferred method of movement of goods and services, is also heavily reliant on the existence of an efficient layout.

Characteristics of a Sub-optimal Layout

- Inventory lying in various locations

- Pallets have to be displaced to get to other pallets

- Safety violations

- Excessive movement of inventory and people within the facility

- Personnel have to walk an additional mile to accomplish their daily tasks

- Low production and low OEE (Overall Equipment Efficiency)

- Delays, bottlenecks, inadequate storage locations

- Material handling constraints

- Process is tied to one or two important machines or areas within the facility, resulting in sub-optimal flow

- Need for expansion by adding space

Our Approach to Create an Efficient Layout

- Study existing processes affecting the layout

- Study process, information and people flow

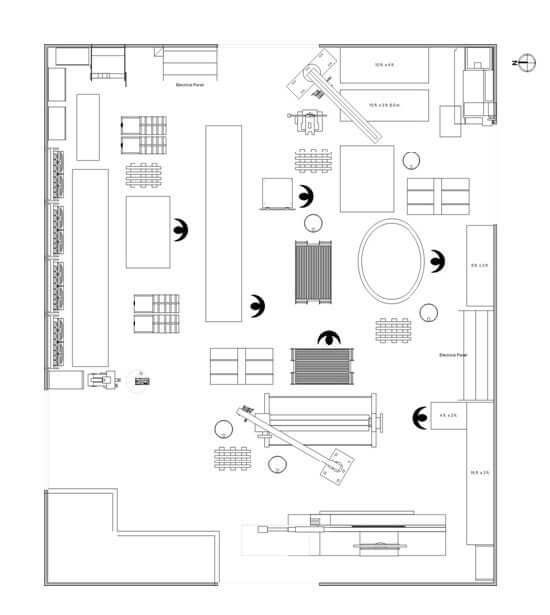

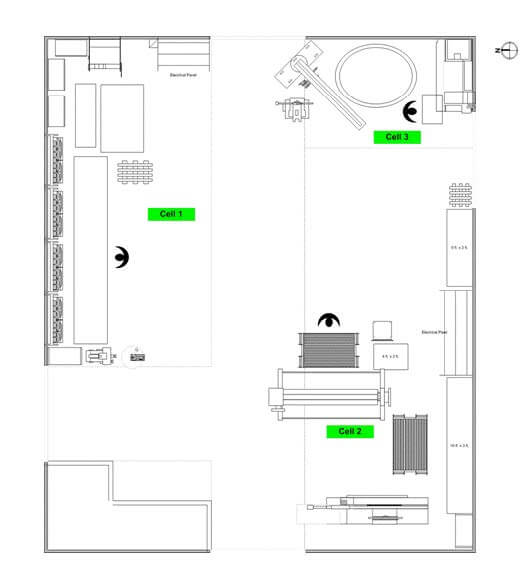

- Draw current layout taking into account the above two points

- Study existing constraints that need to be avoided

- Review new constraints that need to be built into the new layout

- Take into account any updates related to processes and physical assets

- Consider plan for any future additions and enhancements

- Design new layout by considering above constraints and updates

- Draw the new layout

Benefits:

Typical results from our layout optimization approach include:

- Significant savings obtained by eliminating remote warehouse and distribution centers

- 35% reduction in material handling and walking activities

- 50% to 80% availability of retained space, which can be used to add more capacity

- 10% to 30% reduction in lead time (typically production lead times)

- Drop in inventory levels (Raw Materials, Work In Process and Finished Goods Inventory) due to better flow and higher visibility

- Drop in safety-related incidents and increase in worker productivity

- Improved morale and decreased absenteeism