Inventory is an asset in accounting terms, but it is considered a liability in the Lean Manufacturing world.

Why? Because it becomes obsolete, expiration dates need to be tracked continuously, it gathers dust and rust, occupies valuable warehouse space, gets damaged, has to be constantly moved, and has no value to the company or its customers. A company spends its valuable assets, including financial, manpower and time to take care of inventory, without receiving any return on this investment.

Inventory is one of the foundations of manufacturing, and historically, manufacturers have been stocking it in large quantities. Given the current economic situation, and manufacturers’ pursuit of providing more value to their customers, inventory levels need to be optimized. Having too much inventory causes numerous problems and incurs cost, while having low inventory could lead to the loss of sales. Given the evolving habits of the price conscious customer and intense domestic and international competition, it is imperative for manufacturers to carefully assess inventory levels to be profitable. Inventory reduces a portion of the liquidity of any company, and as one manufacturer put it – “I would rather have money in the bank than money lying around on my warehouse shelves”.

Approach

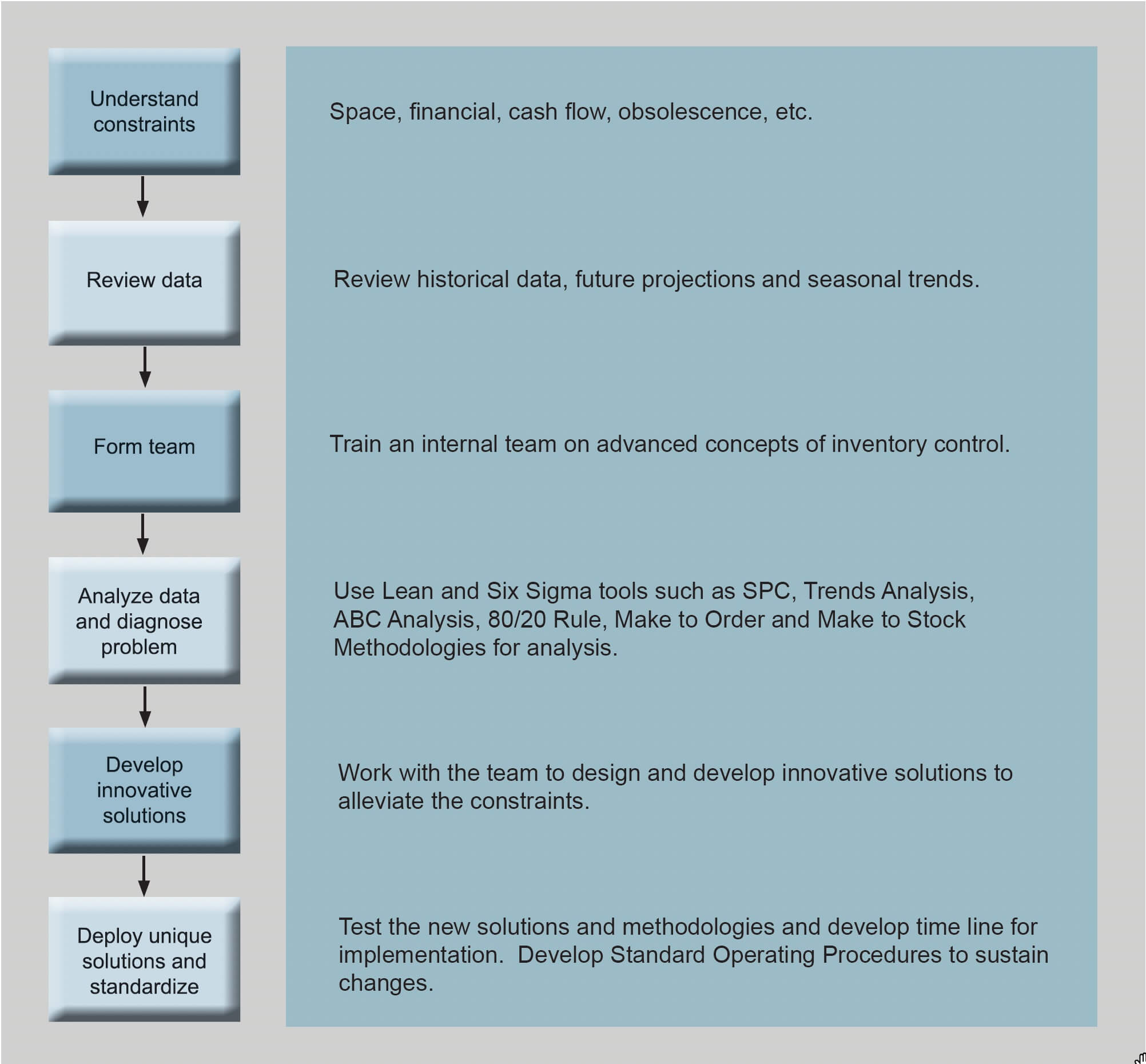

Since the needs of all manufacturers and the requirements of various industries are unique, Manex tailors its approach to meet the needs of the organization. Manex uses Lean and Six Sigma tools to design and implement an inventory control system that will work optimally in the organization. Manex focuses on the following types of inventory:

- Raw Materials

- Work in Progress (WIP)

- Finished Goods

- Obsolete Materials

Manex performs in-depth analysis of all the processes and procedures in place for inventory control and helps develop new procedures as required. Among other things, Manex helps manufacturers develop and implement:

- Robust raw materials ordering processes

- Safety stock levels, re-order points and order quantities for raw materials

- New production scheduling methodologies to optimize WIP

- Improved manufacturing methodologies to meet demanding customer lead time requirements

- Stocking levels for finished goods

- Kanban systems to manage raw materials and finished goods

- Plans for dispositioning obsolete materials and excess inventory

Benefits

- Accurate inventory at all levels

- 25% shorter lead time

- Enhanced cash flows

- Reduction in warehouse space required by up to 80%

- Near zero obsolescence

- Reduction in inventory by up to 75%