By Gene Russell, Manex President & CEO

I wanted to take a look at how California manufacturing is doing during the COVID-19 crisis and think of keys to success we must remember as manufacturing companies, especially now.

Many of our California manufacturers had a poor April and May and a stellar June. However, with the resurgence of COVID-19, this quarter is looking pretty ragged. The level of uncertainty from small to large company CEO’s is really astounding when you consider it against 2019.

U.S. Manufacturing completed a $6.2 trillion year in 2019, generating exports of $1.2 trillion, profits of $507 billion, through 614,884 individual businesses according to an IBIS World industry report. While we tend to think big familiar brands like Ford, Boeing, Exxon; the bulk of the industry includes a lot of small to midsized firms supporting millions of families. It is where innovation happens and that is proven by the R&D stats the government puts out.

Although we are known for beaches, sun, and fun, to those of us in the sector we know that at the State of California contains the largest number manufacturing firms at about 13% of the U.S. total. Other than refineries, biomedical and Tesla we don’t have the giant brands of other states. We are a state with small companies. Regionally, the Southeast is the largest region and the Great Lakes are the second largest in concentrations, driven by automotive supply chains.

As of the end of June 2020, projected unemployment is estimated to be 10.1% although I think it could go deeper. Unemployment fell to 11.1% during the month. New applications for jobless benefits declined but as of this blog they are headed back up. There was a decline in hourly average wage, which can be interpreted a few ways, none of them good for the economy. In manufacturing, supply chain and labor disruptions continue to be issues nationally including Northern California. Bringing back a workforce also burdened by childcare and at-home education adds another layer of difficulty for owners and their employee teams.

As of the end of June 2020, projected unemployment is estimated to be 10.1% although I think it could go deeper. Unemployment fell to 11.1% during the month. New applications for jobless benefits declined but as of this blog they are headed back up. There was a decline in hourly average wage, which can be interpreted a few ways, none of them good for the economy. In manufacturing, supply chain and labor disruptions continue to be issues nationally including Northern California. Bringing back a workforce also burdened by childcare and at-home education adds another layer of difficulty for owners and their employee teams.

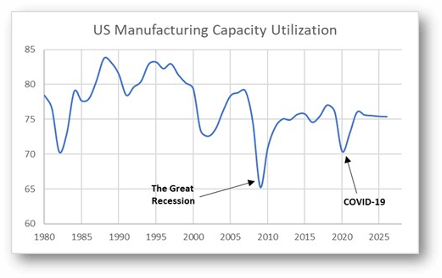

The U.S. officially entered a recession in February 2020. Delayed and rolled-back phased re-openings in July and August threaten the balance of the year. Manufacturing capacity utilization currently sits just above the low trough of the great financial recession of 2007-2009. Manufacturing absorbed 10.36% of the SBA PPP overall and as a state, California business received $68.2 billion in funds. PPP helped retain 51.1 million American jobs for small businesses. It certainly doesn’t replace cratering demand in retail, restaurants, airlines, aerospace, automotive, and even biomedical. Non-COVID-19 related products are suffering from lack of demand from hospitals totally focused on the pandemic.

My perspective in dealing with many of the scrappy (resilient in MBA speak) manufacturers around the region, is that we just have to layer on these difficulties to what we are already dealing with. If you are reading this blog, you probably already know how Manex and the MEP system can help. I will not belabor that subject. Just remember, the monies out there to assist are for you to take and like all resources they are limited. Beyond the current difficulties I want to share with you the IBIS World research firm’s keys to success in manufacturing, I have expanded on a few of them specific to our region and our project experience with manufacturers. These are the “keys to success” to not lose sight of with all the craziness going on.

- Ability to quickly adopt new technology

- Stable supply of key inputs

- Ability to control inventory levels

- Having a high profile in the market

- Quality (ISO)

- Delivery on Time (ability to scale quickly)

- Branding

- History/Reputation

- Innovation

- Ability to actively sell and close new business

- Experienced Workforce

- Effective Cost Controls and Strategies

- Raw Material (average 57% of costs)

- Overhead

- Taxes

- Labor Utilization (average 11.6% of costs)

- Automation

- Plant and Equipment

I am reminded of the term “soldiering through” a time of crisis from my childhood. Let us know what you need in regards to the pandemic and in regards to hitting the keys to success on this list.

About the Author

Gene Russell is President and CEO of Manex and has over 30 years of senior executive strategic planning, operational management, and consulting experience in the manufacturing and technology sectors. With his extensive knowledge of manufacturing operations, he has developed and implemented key strategic initiatives for companies, allowing them to improve performance and achieve profitable growth. He can be reached at grussell@manexconsulting.com.