Beginning construction on a new manufacturing plant is no small task. It takes a great deal of vision, along with a complete understanding of the project scope to ensure that you make all the right moves.

To aid in this process, Manex has compiled a list of 10 crucial steps for planning your manufacturing plant’s construction. Following these guidelines will help you navigate this complex process, and ensure a solid foundation for your project.

Before jumping headfirst into a project as large as building a plant, it’s important to conduct an internal feasibility study. This will include determining the estimated budget for the project, along with potential return on investment. It is also a good idea to familiarize your organization with local regulations, including environmental laws, before getting started laying out the plan for your new manufacturing plant.

1. Location, Location, Location

Much like any real estate project or purchase, choosing the right location for your manufacturing plant is extremely important to your success. Your initial feasibility study should have determined what city, state, or even country you will be building in, but your next decision includes the actual plot of land where your manufacturing plant will be constructed. Will you purchase the land outright, or will it be leased? Consider the long-term benefits of owning the property, versus leasing, such as the ability to expand your facility in the future.

It is also important to take note of access to resources, as well as transportation costs for getting things to and from your plant. If the plant will be located in or around a major population center, this will be easier. Your location will also affect your ability to staff the plant, so be sure to consider this as well.

2. Obtaining Necessary Permits

Regardless of where you choose to build your new manufacturing plant, local, state, and federal permits and regulations will need to be considered. Take particular note of environmental regulations specific to your chosen location. Receiving permits can take time, so it is important to get this process started early to avoid delays. Working with an experienced team of manufacturing consultants, such as those at Manex, can make this part of the process much easier.

3. Getting Your Finances in Order

Before you are ready to break ground, you will need to have a financial plan in place for the project. Budgeting and cost estimation is key to making sure you have the funds needed not only to start, but complete the project. Whether you are self-financing the project, or taking out loans, consider applying for grants designed to spur business in your plant’s location. Some jurisdictions may even offer tax increment financing (TIF) programs, which can help to fund building the plant.

4. Designing Your New Manufacturing Plant

In this step you will need to select a designer who will help you create the blueprints needed to bring your manufacturing building to life. Stakeholders should be involved early in the process to help the designers craft the plant’s layout, and ensure that every functionality you need is accounted for. It can be easy to overlook things like planning for a break room and employee parking lot, so be sure to partner with experienced contractors who know what it takes to build a manufacturing plant.

5. Choosing a Delivery Method for Construction

There are a number of different ways to go about the actual construction of your manufacturing building.

A popular method is hiring a general contractor (GC), who will oversee the entire construction project. This method simplifies the process for yourself, as the contractor will hire and manage a team of subcontractors who will handle each aspect of construction.

Alternatively, a construction manager (CM) approach will allow more owner involvement, with the construction manager acting in an advisory role. The construction manager should be involved early, to advise in the design, budget, and scheduling of the project, as well as overseeing the construction process.

Another popular approach is the design-build (DB) method, in which a single provider handles both the design and construction aspects of the project. This process is advantageous because it can deliver faster completion times, with lower overall costs due to dealing with only one entity.

Be sure to weigh all options, and choose wisely who you partner with, as this is often the most important decision made in your project.

6. Create a Timeline for Your Project

With the help of your construction partners, develop a realistic time for completion of the project. Your timeline should account for the design process to be completed, the permitting process, the actual plant building, and installation of the needed equipment. It is also wise to consider potential delays and develop a contingency plan that can avoid possible downtime and keep you on budget.

7. Identify Your Equipment Needs

The type of manufacturing plant you are building will dictate what type of equipment you will need. For instance, a food manufacturing plant may require refrigeration units or freezers. Some specialized equipment may require specific installation techniques, such as cranes or even foundation requirements. These considerations should be made as part of the overall planning and design process.

8. Consider Future Expansion Plans

During your planning stage, give consideration to your future plans. If you anticipate a large amount of business growth thanks to your new manufacturing plant, developing a long-term growth plan for future add-ons can save you tremendous headaches down the line. For example, you would not want to be limited in your growth potential by not having enough space on your property for future additions.

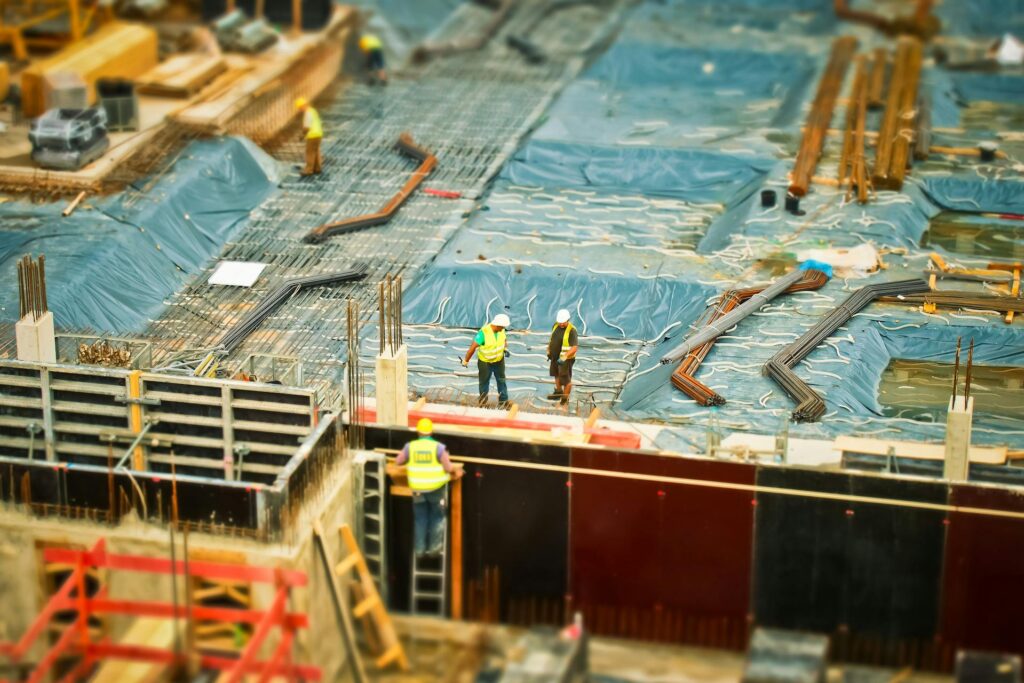

9. Physical Construction of Your Building

It may seem like a small point, but considering how your plant will be physically constructed is an important detail in need of consideration. Plan for the total occupancy of the building (with room for growth), the lighting needs of specific areas, HVAC needs, and even the physical makeup of the walls. You are also going to need a lot of power to run your manufacturing plant, so be sure to account for that in your design process.

10. Implement Safety Procedures

Plan to conduct regular safety inspections during the construction process. There are a lot of moving parts when it comes to building a plant and an unsafe construction environment can ultimately cause delays, financial loss, or worse – loss of life. Take a proactive approach to safety early on in the process. Working with a trusted expert in construction is key to making the process run smoothly.

At Manex, we have helped advise in the layout and production line design in numerous manufacturing plants. Our team of industry experts can help you with the initial planning phase, as well as help you identify the right partners. Contact Manex today to learn more about how we can help you in building or expanding your manufacturing plant.